Efficiency in Manufacturing Operations Starts with a Few Easy Steps

In today's competitive business environment, manufacturers must constantly look for ways to improve efficiency and streamline operations.

Executive Summary:

In today's competitive business environment, manufacturers must constantly look for ways to improve efficiency and streamline operations.

Achieved manufacturing efficiency means ideally having everything in your workday flow – team collaboration, project progress, and data insights utilization. By improving efficiency, manufacturers can reduce costs, increase productivity, and ultimately improve their bottom line.

But can you get there sooner rather than later? And how? Here are some tips tailored to help you improve manufacturing operations management efficiency.

What is Manufacturing Efficiency

Manufacturing efficiency refers to the ability of a manufacturing process to create products with a high level of quality while minimizing waste and maximizing productivity. We measure efficiency in various ways, such as the number of units produced per hour or the percentage of defects in the final product.

Efficient manufacturing often involves optimizing the use of resources, such as materials, energy, and labor. The following factors will immensely help you with this:

- The use of modern technologies

- Better planning and project management

- Process improvements

But there is more to it. Measuring manufacturing efficiency is crucial for manufacturers to remain competitive – in fact, to be able to destroy the competition. Key performance indicators (KPIs) such as production rate, cycle time, defect rate, and uptime show the efficiency level and identify improvement areas. Companies can increase profitability, improve customer satisfaction, and stay ahead by continuously enhancing manufacturing efficiency

Why is Efficiency Important for Manufacturers

Efficiency is important for manufacturers because it directly impacts their bottom line. It affects:

- Production capacity

- Profitability

- Customer satisfaction

Efficient manufacturing reduces costs and improves your product quality. That means you can produce more goods in less time, which means more sales and cash in your pocket.

Achieving efficiency allows manufacturers:

- To offer their products at more competitive prices, increasing their chances of winning over customers and increasing sales.

- To have increased productivity, allowing manufacturers to produce more goods in less time.

- To meet customer demands more quickly and efficiently, which in turn increases customer satisfaction, so customers become repeat customers.

Efficiency also plays a crucial role in product quality. Analysis of manufacturing processes can help identify and correct defects early on, reducing the likelihood of product recalls and improving overall quality. This is especially important for manufacturers in industries such as pharmaceuticals or aerospace, where even minor defects can have severe consequences. And here’s the kicker, being efficient is also good for the environment. You’re reducing your carbon footprint when you’re not wasting materials, energy, and time. Meaning: you can make products that are not only great but also green. It’s a win-win situation.

Manufacturing Productivity vs. Efficiency

So, let’s look at manufacturing productivity, which is all about getting things done while maximizing manufacturing efficiency. Productivity is about meeting deadlines, hitting quotas, and making the most out of every hour. It’s about moving fast and getting things done.

On the other hand, efficiency is about doing things right. It’s like when you’re making a sandwich, and you must put every ingredient in its proper place to make it taste delicious. Efficiency is about reducing waste, optimizing resources, and minimizing errors. It’s about doing things in the most thoughtful way possible.

So, which one should you focus on? Well, it’s not an either/or situation. You need both productivity and efficiency to succeed in manufacturing.

First, you need the right tools and processes. That means using technology like data analytics and project management to streamline your operations. It means:

- Implementing lean manufacturing principles to reduce waste and optimize resources

- Setting clear goals and tracking progress to ensure you’re on the right track

- Using data analytics, project management, and tools for following progress and team conversations

But it’s not just about technology and processes. You also need a team that’s engaged, motivated, and passionate. That means creating an environment of transparency, constant collaboration, alignment, visibility, and clarity of goals and processes.

Manufacturing productivity and efficiency are like the dynamic duo of manufacturing success. You need both to win the game.

Tips to Improve Manufacturing Efficiency

There are various tips that manufacturing companies can follow to improve their efficiency. Let’s explore them now.

Conduct a Thorough Analysis of Manufacturing Processes

The first step in improving manufacturing efficiency is thoroughly analyzing current manufacturing processes. This analysis should include identifying bottlenecks, inefficient operations, and wasteful practices. Тhe best way is to look at the data insights and have a better view of optimizing production processes, reducing waste, and improving quality. By identifying inefficiencies, manufacturing companies can make changes that will positively impact productivity and profitability.

Implement Lean Manufacturing Principles

Lean manufacturing is a production philosophy that aims to eliminate waste and improve efficiency. This approach involves optimizing the value stream, reducing inventory levels, and improving production flow.

Have an Aligned Team

Manufacturing employees must always be aligned around the same goals, objectives, and processes. Having your departments aligned and in the know of what’s happening has a significant impact on productivity and efficiency.

Use the Right Technology

The right tools that a manufacturing team uses should bring together communication, collaboration, and productivity in one place. Such a platform can improve manufacturing efficiency by providing a centralized location for all company data, enabling real-time collaboration and better team communication. An app like an all-in-one digital workplace reduces the time it takes to find information, improves collaboration across teams, and streamlines workflows, leading to better overall efficiency.

What Software Should I Use to Track Manufacturing Efficiency

The software you should use to track manufacturing efficiency will depend on your needs and goals – and has a massive role in your team and company’s success. We will now focus on what are the benefits of choosing an all-in-one digital workplace.

Everything Together

An all-in-one digital workplace is a platform that combines all the elements your team needs to do their jobs, including task tracking, chat, document sharing, project management, and more.

Increased Productivity

By consolidating all your work tools in one place, you can reduce the time and effort required to switch between different applications and systems, enabling employees to work more efficiently.

Better Collaboration

Facilitate better team collaboration by providing a central communication and document-sharing location. This breaks down silos and improve cross-functional collaboration.

Enhanced Security

With all your work tools in one place, it can be easier to maintain consistent security policies and protocols across your organization, reducing the risk of data breaches or other security incidents.

Cost Savings

An all-in-one digital workplace can help reduce the cost of IT infrastructure, software licenses, and maintenance by consolidating multiple systems and tools into a single platform.

How Can Slingshot Help You Improve Manufacturing Efficiency

Аs an all-in-one digital workplace with robust data analytics capabilities (allowing for a GREAT view of your data insights for everyone on the team), Slingshot can easily be described as a manufacturing team’s dream. Here is why.

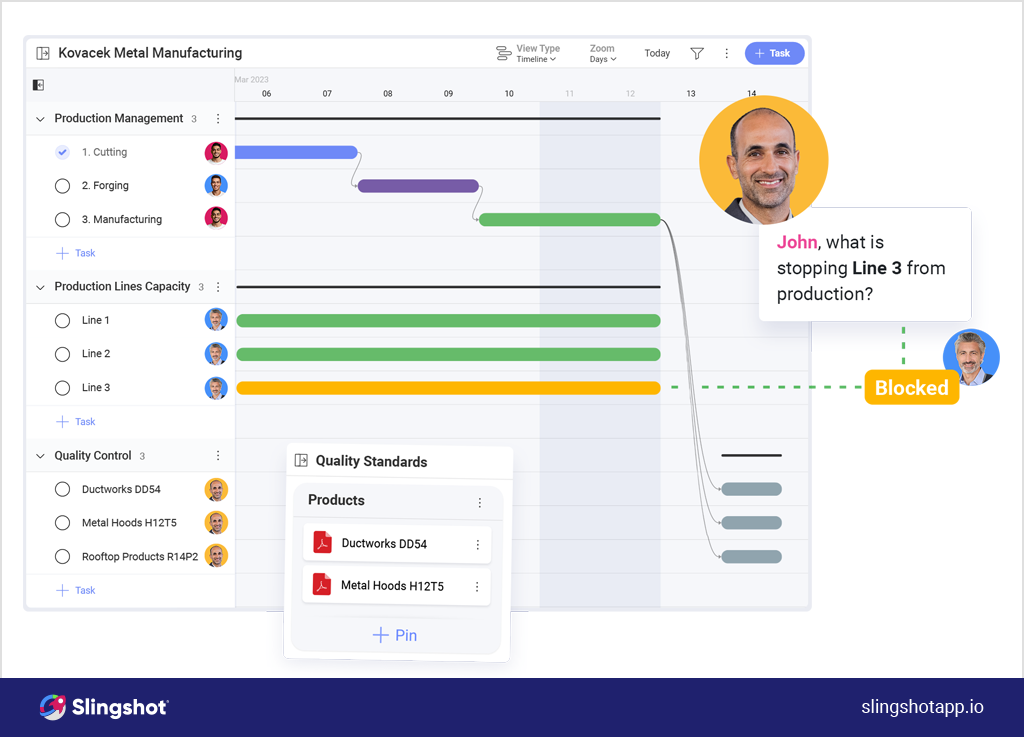

Combine All Production Processes in One App

Every chat, task, document, and data is kept in a centralized and organized hub. Slingshot empowers you to manage and monitor your company’s manufacturing processes and optimize project timelines. That way, you can reduce roadblocks and hit goals faster.

Intuitive Data Dashboards

Slingshot’s ability to create intuitive visualizations from your raw data pulled from multiple sources saves you time and resources and provides easy data-driven decision-making. Connect to all your manufacturing data sources with a few clicks, then easily share and discuss with your team in-app or create a task from a dashboard.

Visibility at Any Point

Slingshot provides better visibility into teams’ work with due dates of tasks, easy project tracking, and organization of workspaces. We simplify sharing information with the engineering, procurement, maintenance, and production teams by pinning or uploading every file and update you need. View ownership, set dependencies, and align every department in one app.

To see what Slingshot’s made out of, start your free trial now and see your results soar.

Related Articles

Ready to grow your business 10x with AI decision-making?

Request a Free Demo of SlingshotSHARE THIS POST